The Evolving Landscape of Weld Angle Brackets: A Closer Look at Market Trends

The weld angle brackets market is undergoing a steady transformation, a development that might appear intimidating at first glance but offers a wealth of opportunities for those willing to take a closer look. Over the next decade, the market is forecast to grow from USD 1.7 billion in 2025 to approximately USD 2.2 billion by 2035, boasting a modest 2.8% compound annual growth rate. This editorial provides an opinionated overview of the market’s directions, addressing the market’s growth drivers, innovative shifts, and potential obstacles—all while steering through the tricky parts and tangled issues that give the sector its unique character.

Understanding the Building Blocks: Market Fundamentals and Material Dynamics

The backbone of the weld angle brackets market is closely tied to the structural design needs of modern construction practices. The market is heavily influenced by the rising demand for standardized, pre-engineered solutions that ensure consistent performance in residential, commercial, and industrial settings. Rather than relying on site-built, fabricated solutions, the industry is increasingly moving toward load-rated brackets that promise a dependable, even connection. This change is creating a landscape that is both exciting and filled with its own set of confusing bits.

Steel’s Dominance and Aluminum’s Niche Role

Steel continues to be the material of choice, capturing roughly 68.0% of market share. Its superior load-bearing capacity, optimized carbon composition, and robust weld compatibility make it a key material for tackling the fine points of structural reliability and installation efficiency. Meanwhile, aluminum, recognized for its lightweight properties and corrosion resistance, serves specialized markets such as coastal construction. Although aluminum does not dominate in terms of market share, its unique features serve niche roles in areas where weight reduction and environmental resistance are super important.

Table: Material Comparison in Weld Angle Brackets Market

| Material | Market Share | Key Advantages | Typical Applications |

|---|---|---|---|

| Steel | 68.0% | Superior load capacity, robust weld compatibility | Residential, commercial, industrial structures |

| Aluminum | Remaining share | Lightweight, corrosion resistant | Coastal, marine, specialized applications |

These material choices not only determine product performance but also dictate construction workflows and installation practices. As construction companies continue to assert the need for quick installation and minimal on-site rework, the transition from traditional site-fabricated systems to pre-engineered brackets becomes increasingly critical.

Modernizing Construction: Prefabrication and Digital Integration

One of the most noticeable trends shaping the market involves the expansion of prefabrication and modular building practices. Contractors are increasingly seeking bracket designs that cater to streamlined installation processes, facilitating rapid assembly and precise alignment. This shift towards modular, off-site fabrication means that components must be manufactured to exacting standards, reducing the room for error and minimizing those nerve-racking on-site adjustments.

Digital Tools and BIM Compatibility

The integration of digital technologies, such as Building Information Modeling (BIM), into the bracket sourcing process is a game changer. Engineers and contractors now have the option to source components from BIM-compatible libraries, ensuring that every part fits into a broader, digitally mapped construction plan. This integration helps reduce the twisted complexities and hidden technical bits that can arise from manual measurement errors and inconsistent manufacturing standards.

Key Benefits of Digital Integration

- Enhanced accuracy in layout planning

- Reduced on-site measurement errors

- Smoother integration with modern construction workflows

- Faster decision-making and material verification

By blending traditional manufacturing strengths with digital innovations, the weld angle brackets market is positioning itself as a critical enabler for the future of construction technologies. This not only enhances overall project efficiency but also redefines how safety and reliability are approached in structural designs.

Regional Dynamics: Growth Drivers and Geographic Shifts

The market dynamics for weld angle brackets are not homogeneous across the globe. Regional construction trends and differing building code standards contribute to a landscape that is loaded with problems and subtle differences. In this section, we take a closer look at how certain regions are fueling or slowing the market’s pace.

Asia Pacific: The Powerhouse of Construction Expansion

Asia Pacific, especially countries like China and India, is witnessing robust construction activity fuelled by urbanization and government infrastructure projects. With China projected to grow at a 3.8% CAGR and India close behind at 3.5%, the region is quickly becoming the epicenter of new building developments. This geographic twist is primarily driven by:

- Rapid urbanization and infrastructural investments

- Increased adoption of prefabricated construction methods

- Localization strategies that reduce import dependency

- Government policies geared towards standardizing building codes

Local manufacturers and distributors in these markets are seizing the opportunity to position themselves as key players by investing in advanced bracket systems that can meet both domestic and international construction standards.

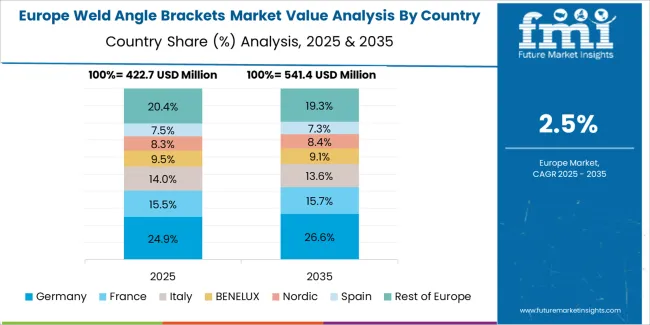

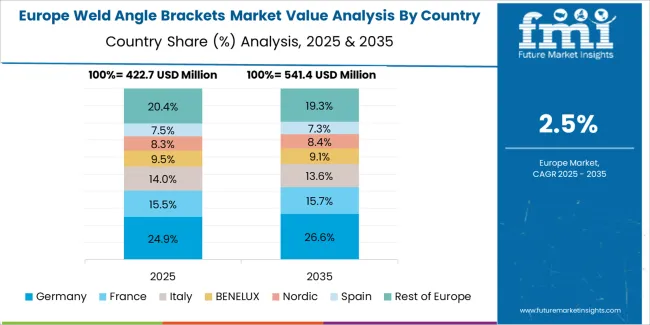

Europe and North America: Steady Growth with Established Standards

While Europe and North America may not experience the same growth spurt as their Asia Pacific counterparts, they still hold significant parts of the market. The construction sectors in these regions are shifting toward advanced fastening technologies that are both efficient and comply with stringent building codes. Countries like Germany, the United States, and the United Kingdom are ensuring their markets remain on track with annual growth rates ranging from 2.1% to 2.7%.

Table: Regional CAGR Comparison (2025-2035)

| Region/Country | CAGR (%) |

|---|---|

| China (Asia Pacific) | 3.8% |

| India (Asia Pacific) | 3.5% |

| Germany (Europe) | 3.2% |

| Brazil (Latin America) | 2.9% |

| United States (North America) | 2.7% |

| United Kingdom (Europe) | 2.4% |

| Japan (Asia Pacific) | 2.1% |

These regions are characterized by established building infrastructure paired with a readiness to incorporate innovative fastening systems. In North America, for example, developers are increasingly opting for weld angle brackets in residential and commercial projects where precision and consistency are key.

Opportunities and Challenges: Untangling the Problems and Opportunities in the Market

Despite a generally positive outlook, the weld angle brackets market is not without its tricky parts. Various challenges exist alongside the significant opportunities that lie in technological integration and material optimization.

Key Growth Opportunities for Manufacturers

Several strategic pathways present significant revenue potential, each addressing different aspects of market demand and offering avenues for innovation:

- Steel Material Leadership & Advanced Formulation Optimization: By reinforcing the dominant steel segment with enhanced formulations and corrosion-resistant coatings, companies can unlock premium pricing strategies while improving structural reliability.

- Asia Pacific Construction Expansion & Market Localization: Focused efforts on local manufacturing capabilities and partnerships can better cater to the large-scale residential and infrastructural efforts underway in Asia Pacific markets.

- Residential Market Dominance & Construction Integration: With residential applications commanding the largest market share (around 55%), targeted product development for home construction can lead to significant market penetration.

- Commercial Application Diversification: Expanding bracket designs to meet high load and seismic resistance requirements can open opportunities in the commercial sector.

- Aluminum Material Development & Lightweight Positioning: Niche markets requiring weight reduction and enhanced environmental resistance offer a fertile ground for aluminum bracket innovations.

- Prefabricated Construction & Modular Building Integration: Specialized designs that cater to prefabricated assembly and modular integration can boost efficiency and reduce on-site installation times.

- Coating Innovation & Corrosion Protection Development: The development of advanced coating techniques—such as hot-dip galvanization and powder coating—stands to improve the durability and longevity of the brackets.

Each of these pathways represents a super important opportunity to not only improve product performance but also drive growth in a competitive marketplace. With companies like KD FASTENERS, Masterpiece Taiwan, STL Fasteners, and American Bolt & Screw leading the way, innovation remains at the forefront of market evolution.

Tackling the Tough Parts: Challenges in the Weld Angle Brackets Market

While the future looks promising, companies face several off-putting challenges that require careful attention:

- Rising Raw Material Costs: Price fluctuations in steel and aluminum can translate into unpredictable production expenses.

- Technical Performance Limitations: Corrosion susceptibility and inconsistent welding quality in high-moisture and coastal environments may lead to reduced bracket performance.

- Fragmented Building Codes: Varying standards and codes across different geographic regions create complications and require manufacturers to customize their products for local acceptance.

- Competitive Pressure: With a moderate market concentration and a handful of key players dominating over 40% of global share, smaller companies need to seriously factor in the headwinds when competing on price and technology.

Addressing these tangled issues is key to ensuring that the market remains on a growth trajectory over the coming decade. Manufacturers must consistently work on refining production processes and technical standards to stay ahead of these challenges.

Engineering Excellence and the Digital Revolution: Modernizing the Market

The fusion of advanced engineering with digital innovation is rapidly rewriting the rules of the game in the weld angle brackets industry. While traditional methods have always been centered on material performance and structural integrity, the new wave of digital integration is reshaping how products are designed, tracked, and deployed.

The Role of Digital Integration in Fastening Solutions

Engineering excellence is no longer solely about the physical properties of steel or aluminum. Today’s market leaders are required to incorporate digital monitoring systems, quality controls, and BIM compatibility into every product they develop. Here are some ways in which technology is influencing the sector:

- Real-Time Data Tracking: Digital dashboards and online platforms allow for continuous monitoring of product performance and adherence to quality standards.

- Automated Quality Verification: Advanced sensors and software solutions help ensure that each bracket meets the pre-defined specifications before leaving the production line.

- Enhanced Digital Libraries: BIM-compatible component libraries provide engineers with easy access to standardized components, reducing measurement errors and streamlining installation processes.

- Supply Chain Integration: Digital platforms allow for better coordination with suppliers, reducing lead times and the potential for miscommunication.

These digital shifts are not just a trend; they are a necessary evolution that empowers contractors to figure a path through the maze of modern construction challenges with greater accuracy and reliability.

Managing Your Way Through Global Construction Trends

The interplay between global construction trends and fastening technologies cannot be ignored. As countries modernize and invest in new infrastructure, the need for advanced structural components such as weld angle brackets grows. Let’s take a closer look at how different countries are contributing to this evolution:

Case Study: China’s Rapid Urbanization

China’s fast-paced urban development has set the stage for rapid growth in the weld angle brackets market. With construction projects ranging from residential areas to sprawling commercial complexes, Chinese contractors are prioritizing quick installations and high reliability. The investment in modern fastening systems is driven by:

- Large-scale urban development initiatives

- Demand for consistent, pre-engineered solutions

- Adoption of digital tools to streamline planning and execution

This environment, though challenging with its own nerve-racking twists and turns, is ripe with opportunities for innovation and expansion. Local companies are increasingly investing in research and development, ensuring that their products meet international standards while catering to regional needs.

Germany: Precision Engineering and Structural Integration

Across the continent, Germany remains a beacon of engineering excellence. With high standards for structural performance and a keen eye on fine shades of modern safety protocols, German manufacturers continue to set benchmarks in the global market. Key factors driving growth in Germany include:

- Adherence to rigorous EU safety and performance standards

- Collaboration between traditional fastener companies and digital technology partners

- Investment in automation and precision manufacturing techniques

The German model, characterized by its precision and a firm commitment to continuous improvement, highlights how blending traditional expertise with modern digital practices can lead to sustainable market leadership.

North America: Balancing Tradition and Innovation

In the United States and Canada, there is a harmonious balance between long-held construction practices and the new wave of technological innovation. As American contractors increasingly focus on meeting stringent building codes and achieving expedient project timelines, the need for quick-to-install and reliable weld angle brackets becomes super important. Initiatives such as enhanced digital quality control and BIM integration are steadily gaining ground, ensuring that products are not only effective but also consistently reliable across various applications.

Future Outlook: Paving the Way for Sustainable Growth

Looking ahead, the weld angle brackets market remains poised for steady growth despite the nerve-racking challenges and off-putting twists that exist. Key factors contributing to a positive future outlook include:

- Incremental advances in material science, particularly in steel and aluminum formulations

- The ongoing digital revolution in manufacturing and supply chain management

- Rising construction activities globally, with a marked focus on prefabricated and modular building techniques

- Government initiatives in emerging markets aimed at modernizing building codes and construction practices

In this environment, companies that can effectively mix engineering excellence with disruptive digital strategies are likely to come out on top. This calls for a dual focus: one that respects the traditional, proven methodologies of structural framing while embracing modern digital tools capable of streamlining and verifying performance.

Key Considerations for Industry Stakeholders

For decision-makers and industry stakeholders, several key considerations will help ensure sustainable success in the years ahead:

- Investing in R&D: Continuous research into new coatings, corrosion resistance, and material improvements is critical.

- Digital Adoption: Embracing BIM-compatible tools and real-time data tracking systems will help reduce on-site errors and improve overall project efficiency.

- Strategic Partnerships: Collaborating with regional manufacturers and distributors, especially in fast-growing markets like Asia Pacific, can create a competitive edge.

- Compliance and Standardization: Actively engaging with regional regulators to streamline and standardize building codes will help ensure global market acceptance.

- Flexibility in Product Lines: Developing a broad product portfolio, from advanced steel formulations to specialized aluminum brackets, will enable companies to address a wide range of construction requirements.

The confluence of these factors means that while the market is loaded with confusing bits and on-edge issues, the path toward growth is clear for those who manage to work through the tricky parts with determination and foresight.

Conclusion: Embracing Change in a Transforming Industry

The weld angle brackets market is at an inflection point, where traditional methods meet modern digital advancements and innovative engineering solutions. The shift from site-built designs to pre-engineered, load-rated solutions has opened the door for improved installation efficiency, enhanced digital integration, and a more harmonious alignment with global construction trends. While rising raw material costs, technical performance challenges, and regional regulatory differences remain tricky parts of the landscape, the overall trend is one of steady, albeit modest, growth.

For industry participants, the next decade holds immense promise if they can take a closer look at the evolving needs of the market and adjust their strategies accordingly. Whether it’s investing in advanced steel formulations, embracing digital integration, or forging strategic local partnerships in emerging regions, the opportunities are as diverse as they are promising.

In conclusion, the future for weld angle brackets is not just about maintaining the status quo; it is about adapting to a complex, ever-changing construction environment with agility and foresight. With the right balance of traditional engineering and modern digital tools, stakeholders can confidently steer through the confusing bits and intricate challenges that lie ahead, ensuring that the market remains robust, innovative, and ready for the demands of tomorrow.

As we look forward, it is clear that continued advancements in materials, technology, and global construction practices will shape the landscape in ways we are only beginning to imagine. For those willing to dig into the details and invest in the right innovations, the weld angle brackets market offers a wealth of opportunities that are not just promising but vital in supporting the future of global construction.

Originally Post From https://www.futuremarketinsights.com/reports/weld-angle-brackets-market

Read more about this topic at

Weld Angle Brackets Market | Global Market Analysis Report

Weld Brackets in the Real World: 5 Uses You’ll Actually …