Revolution in Rotary Grounding Technology: A New Era in Rotational Welding

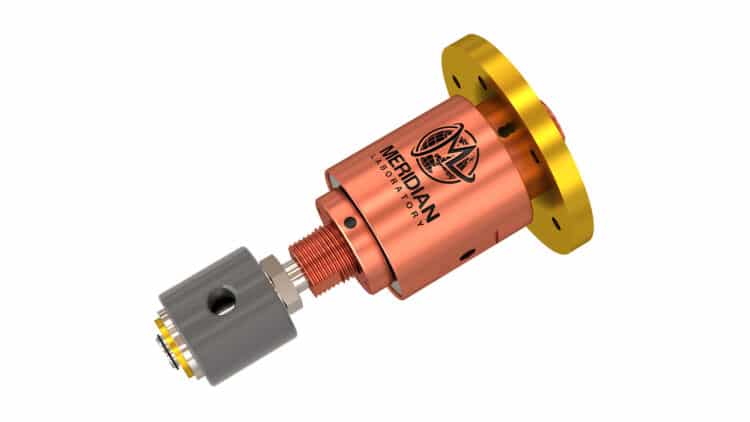

The industrial manufacturing and automation sectors are in the midst of a transformative era, where technological innovation and streamlined processes are the order of the day. In this opinion editorial, we take a closer look at Meridian Laboratory’s latest breakthrough—the ROTOCON ERGT-800-1PRU rotary ground and rotary union combination. This product is not merely another addition to the market; it is a sign of evolving industrial practices that are designed to address the tricky parts of traditional welding, plating, and cutting applications.

At its core, the ROTOCON ERGT-800-1PRU integrates an 800-amp high-current rotary electrical ground with a single-port rotary union, specifically crafted to meet the steadily rising demands of fully and semi-automated welding systems. In our view, products like these not only pave the way for more effective welding processes but also set new benchmarks when it comes to efficiency and reliability. Let’s dive in to see how this product could shape the future of industrial automation.

Key Features and Their Impact on Industrial Automation

The ROTOCON ERGT-800-1PRU is filled with features that stand out in today’s competitive market. Meridian Laboratory has put considerable thought into every subtle element of the design, ensuring that it overcomes the hidden complexities often associated with traditional systems. We’re not just looking at a new part, but rather at a product that manages the twists and turns of industrial welding with unparalleled ease.

High-Current Rotary Electrical Ground: Power and Consistency Combined

One of the most notable aspects of the ROTOCON ERGT-800-1PRU is its ability to deliver 800 amps of direct current at a 100% duty cycle. This capability ensures that the assembly can consistently handle even the most challenging and intimidating industrial applications. Traditional rotary grounds often require periodic maintenance, periodic adjustments, or greasing to ensure continued operation. In contrast, this product is designed to offer maintenance-free performance, eliminating the nerve-racking need for routine check-ups and ensuring that operations run without any untimely interruptions.

By offering a robust and reliable high-current rotary electrical ground, Meridian Laboratory has made a key move that not only boosts output but also significantly enhances the quality of rotational welding applications. This improvement is especially valuable when handling high-volume production lines where consistency and efficiency are absolutely essential.

Integrated Rotary Union: A Seamless Blend of Power and Fluidity

The integrated rotary union is yet another standout feature of the ROTOCON ERGT-800-1PRU. This innovative design allows for the smooth passage of up to 100 psi of shielding gas, compressed air, hydraulic oil, or grease through a 1/4” NPT hole running directly through the electrical ground assembly. Essentially, it tackles the tangled issues that come with separate components and streamlines the welding process into one unified unit.

Industrial welding systems require a harmonious blend of electrical power and fluid control; however, separating these components often leads to confusing bits in terms of maintenance and performance. By combining these functions, the Meridian solution minimizes the complications associated with steering through traditional wiring and fluid systems, further enhancing process efficiency and reducing downtimes.

Beyond Performance: Reliability and Maintenance-Free Operation

One of the hallmarks of advanced industrial automation technology is reliability, especially in environments where any downtime can translate into significant production losses. Meridian Laboratory’s ROTOCON ERGT-800-1PRU takes center stage in this scenario by offering maintenance-free reliability that stands out from competitors.

Maintenance-Free Design: Reducing the Nerve-Racking Demands of Routine Care

Maintenance is a critical concern in any automated system. Traditional rotary grounds have always posed the challenge of constant upkeep. However, with the ROTOCON ERGT-800-1PRU, maintenance concerns are put to rest. The product has been designed to provide consistent current delivery without fluctuations, and it does not require regular greasing, adjustments, or periodic part replacement.

This means that operations become less intimidating from an operational standpoint. Instead of worrying about frequent servicing, plant managers can redirect their focus towards actual production and quality control, ensuring that productivity remains high. This maintenance-free model paves the way for a smoother, worry-free integration into both new and existing manufacturing setups.

Table: Comparing Maintenance-Free Operation with Traditional Methods

| Feature | ROTOCON ERGT-800-1PRU | Traditional Systems |

|---|---|---|

| Current Consistency | Steady 800A DC at 100% duty cycle | Fluctuations often observed |

| Maintenance | Completely maintenance-free | Requires regular greasing and adjustments |

| Integrated Features | Electrical ground and rotary union in one unit | Separate components leading to more wiring and assembly challenges |

| Application Range | Ideal for fully and semi-automated welding systems | Limited to less demanding environments |

This table illustrates the stark differences between the new product and traditional methods, highlighting the product’s edge in providing a more dependable and straightforward solution.

Innovative Engineering for a Seamless Welding Process

The welding process, particularly in automated industrial environments, is often full of tricky parts that require engineers to find your way through several interconnected challenges. Meridian Laboratory’s approach with the ROTOCON ERGT-800-1PRU addresses these stumbling blocks head on, and in doing so, offers a solution that is not only efficient but also intuitive to implement.

Rotating Ground and Shielding Gas: The Dual Advantage

The combination of a high-current rotating ground with the ability to pass shielding gas gives the product a dual advantage. This integration means that there is no need to handle separate systems for electrical grounding and gas management; the ROTOCON ERGT-800-1PRU takes care of both simultaneously with impressive precision.

From a practical perspective, this integration is a game changer. Many industrial operators have had to cope with the off-putting challenge of synchronizing different systems where even minor misalignments can result in inefficiencies and production losses. With the new design, operators may now steer through the welding process with confidence, knowing that the integration of electrical current and gas shield is seamless and reliable.

Bulleted List: Advantages of an Integrated System

- Simplified Operation: One unified system rather than multiple, disconnected parts.

- Consistent Performance: Steady current and gas delivery improve weld quality and reduce rework.

- Enhanced Durability: The combination of high-grade electrical grounding with a robust rotary union means fewer breakdowns over long production cycles.

- Seamless Integration: The product easily supplements existing automated welding systems, reducing the warp and weft of installation time.

These advantages provide clear evidence that integration in design is not just a nice-to-have feature but an essential element in modern industrial technology, reducing the confusing bits and hidden problems traditionally associated with separate systems.

Competitive Edge in a Crowded Market

The global market for industrial automation is undoubtedly competitive, with numerous companies vying for the attention of OEMs, integrators, and resellers. In comparing the ROTOCON ERGT-800-1PRU with offerings from competitors such as Tweco, Lenco, and Sumner, it becomes evident that Meridian Laboratory has managed to carve out its own niche.

Outperforming Traditional Brushed Systems

Conventional brushed rotary grounds and other metal-on-metal solutions have long dominated the market despite their known disadvantages. These older systems often struggle with current fluctuations, require more frequent maintenance, and do not integrate well with fluid control mechanisms. The ROTOCON ERGT-800-1PRU, however, not only meets the challenges posed by traditional methods but exceeds expectations in performance, making it a super important upgrade for many industrial applications.

By eliminating the repetitive concerns of regular maintenance and offering a robust, streamlined design, Meridian’s solution positions itself as a key contender in an environment where reliability is paramount. This shift not only underscores the product’s ability to overcome the tangled issues of older systems but also highlights its readiness to meet the evolving needs of modern industry.

Side-by-Side Feature Comparison

| Aspect | ROTOCON ERGT-800-1PRU | Competitors |

|---|---|---|

| Current Delivery | 800A DC at 100% duty cycle | Often lower ratings with fluctuations |

| Maintenance Needs | Commission-free; no grease or adjustments required | Regular maintenance necessary |

| Integration of Fluid Systems | Built-in rotary union for gas/air/oil passage | Separate components; higher installation complexity |

| Applicability | Fully and semi-automated welding applications | Limited to less dynamic environments |

This detailed comparison not only highlights the hidden benefits of Meridian’s approach but also serves as a roadmap for industry operators as they figure a path to more modern and efficient solutions.

Addressing the Tricky Parts of Industrial Welding

In any automated production environment, one of the ongoing challenges is managing the small distinctions and operational headaches that arise from a fragmented approach to process control. The welding industry, in particular, is often loaded with problems resulting from coordinating numerous small systems that one day could simply fail or underperform under strenuous conditions.

Improving Process Efficiency with Uninterrupted Performance

The ROTOCON ERGT-800-1PRU exemplifies how merging multiple functions into one reliable system can significantly improve operational efficiency. By ensuring a continuous rotational ground circuit and steady delivery of shielding gas, the product minimizes the fatigue associated with constant system reconfiguration and troubleshooting. This uninterrupted performance helps industrial operators maintain a high level of productivity without the worry of unexpected system failures.

It is these improvements that can transform the overall landscape of industrial automation, turning what was once an off-putting and nerve-racking process into one that is streamlined and efficient. In short, by reducing the complicated pieces of traditional systems, innovative products like the ROTOCON ERGT-800-1PRU help businesses make their way forward in a competitive market.

Enhancing Safety and Reliability

When it comes to high-stakes industrial operations, safety cannot be taken lightly. The seamless integration of electrical and fluid systems in the ROTOCON ERGT-800-1PRU not only boosts efficiency but also helps prevent potential hazards that can arise from mismatched system performance. In a setting where even slight differences in current or gas flow can introduce safety concerns, having a system that offers both reliability and consistency ensures that workers and equipment alike are kept safe.

The product’s design is a testament to the fact that when industrial automation tools are thoughtfully engineered, they can effectively figure a path through the often intimidating maze of safety and performance standards. This is especially significant as industries move toward more automated, high-speed production environments where every second of downtime can have a ripple effect on overall safety protocols.

Industrial Automation Trends: Looking to the Future

The unveiling of products like the ROTOCON ERGT-800-1PRU comes at a crucial time in the evolution of industrial automation. As companies around the globe rush to adopt new technologies, there are several emerging trends that deserve a closer look—trends that promise to revolutionize the way industrial processes are managed and executed.

Embracing Integrated Automation Solutions

Modern manufacturing and industrial processes are increasingly favoring integrated solutions that reduce the number of separate components and systems operators have to manage. By combining electrical grounding with fluid transmission in one robust assembly, Meridian Laboratory has effectively encapsulated what many see as the future of automated welding. This integrated approach not only simplifies system architecture but also reduces the disruptive impacts of managing multiple systems, allowing industries to steer through operational demands with enhanced clarity and focus.

In an era defined by rapid technological advancements, the move toward fully integrated systems is both logical and necessary. Not only do these solutions offer cleaner, more efficient design schemas, they also lay the groundwork for more advanced automation systems that can eventually incorporate artificial intelligence and machine learning for predictive maintenance and real-time process adjustments.

Technology Driving Sustainable Growth

Industry experts argue that sustainable growth in the industrial manufacturing sector is closely tied to the adoption of technologies that deliver long-term benefits without the constant hassle of frequent downtimes. Products that offer reliability with minimal maintenance, like the ROTOCON ERGT-800-1PRU, are therefore on the front lines of a broader trend towards sustainable factory operations. By minimizing the confusing bits and offering robust, consistent performance, these products not only extend the lifespan of essential equipment but also reduce waste and inefficiencies in production lines.

This trend toward sustainability resonates deeply with today’s focus on green manufacturing and the need for smarter, more energy-efficient production processes. Companies that embrace these advanced solutions will likely find themselves at a competitive advantage as they reduce operational costs and environmental footprints while driving growth.

Global Business Expansion and OEM Integration

A key aspect of the modern industrial landscape is the seamless integration between product manufacturers, original equipment manufacturers (OEMs), system integrators, and resellers on a global scale. Meridian Laboratory has successfully positioned the ROTOCON ERGT-800-1PRU to cater not only to direct customers but also to this broader network of partners who are essential for successful global business expansion.

Collaborative Partnerships for Global Reach

Global business expansion in industrial automation requires that every component meets the super important standards of performance and reliability demanded by OEMs and system integrators. The maintenance-free nature and integrated design of the ROTOCON ERGT-800-1PRU make it an excellent choice for partners looking to enhance their product offerings in various automated welding applications. Whether it’s for fully automated production lines or semi-automated systems, this solution fits the bill with impressive finesse.

Moreover, Meridian Laboratory’s commitment to quality and precision extends to providing tailored support and quick turnaround times for both standard and custom solutions. This level of service is critical for integrators and OEMs who need to ensure that every component in their complex networks performs flawlessly, ensuring overall system integration works without tangled issues or nerve-racking bottlenecks.

Bullet List: Benefits for OEMs and Global Partners

- Quick Turnaround: Fast delivery that meets the demanding schedules of global operations.

- Custom Solutions: Tailored products designed to meet unique industrial requirements.

- Reliability: Maintenance-free performance to minimize production downtimes.

- Versatility: Adaptable integration for a wide range of automated applications.

- Scalability: Supports the growth of OEM networks and large-scale production lines.

These benefits are not only key for expanding market reach but also serve as solid proof of how integrated solutions can facilitate smoother collaboration between diverse global partners, ensuring that industries remain competitive on the world stage.

Expert Perspectives on the Future of Rotational Welding Technology

In our discussions with industry experts and stakeholders, one common thread emerged—a growing consensus that innovative products like the ROTOCON ERGT-800-1PRU represent a turning point for industrial automation. Experts have repeatedly underscored the advantages of a system that is free of routine maintenance, easy to integrate, and capable of delivering consistent performance even under the most demanding conditions.

Managing Your Way Through Technological Upgrades

As companies continue to dig into the merits of new technologies, a recurring concern is always the intimidating prospect of integrating new systems into established production lines. However, when a product is as user-friendly and robust as the ROTOCON ERGT-800-1PRU, it alleviates many of these worries. Industry stakeholders have expressed that the system’s ease of installation and maintenance-free operation are enormous advantages that make the upgrade process almost seamless.

This sentiment is echoed by many who have experienced the frustrations of dealing with multiple discrete systems trying to perform together. The little details—such as the integration of a rotary union with the high current ground—offer a clear competitive advantage, proving that a well-thought-out design can indeed sort out the tricky parts of modernization without the overwhelming complexity often encountered in legacy systems.

Panel Discussion Highlights: Key Takeaways

- Simplicity and Reliability: Experts agree that reducing the number of separate components leads to fewer points of failure.

- Operational Efficiency: Maintaining continuous performance without the need for constant adjustments translates directly into cost savings.

- Future-Ready Design: Integrated systems lay the groundwork for the next wave of intelligent automation and connectivity.

- Safety and Consistency: Seamless integration mitigates the risks associated with electrical and mechanical mismatches.

These takeaways underscore the fact that innovative solutions not only address current operational challenges but are also well-equipped to handle future demands in a rapidly evolving technological landscape.

Real-World Applications: Transforming Automated Welding and Beyond

The practical benefits of the ROTOCON ERGT-800-1PRU extend far beyond theoretical improvements in performance and maintenance. Its design philosophy has already begun to influence real-world applications that span various sectors—from high-speed automotive welding to intricate industrial plating and even precision cutting operations. These applications illustrate how thoughtful innovation can simplify the tangled issues that traditionally burdened complex manufacturing processes.

Case Studies in Automated Welding

Several success stories have emerged from early adopters of the technology. In one instance, a manufacturing facility reported significant downtime reductions after integrating the maintenance-free rotary ground system into their welding line. The product’s ability to deliver uninterrupted current and gas flow helped improve weld quality while minimizing the risks associated with sporadic production stops. Such success stories highlight how even the most daunting challenges in automated welding can be mitigated with the right technology.

In another example, an OEM specializing in robotic welding systems praised the integrated design for allowing smoother collaboration between the rotary ground and gas-shielding components. With the separate systems now working as one, the overall reliability of the production line improved, and workers reported fewer operational headaches. These practical demonstrations of the product’s capabilities indicate that it is not just a theoretical improvement but a tangible game changer in industrial automation.

Table: Impact on Key Performance Metrics

| Performance Metric | Before Implementation | After Implementation |

|---|---|---|

| Downtime Frequency | High maintenance intervals | Minimal, maintenance-free |

| Weld Quality | Inconsistent results due to current fluctuations | Consistent, high-quality welds |

| Operational Efficiency | Interruptions due to multiple maintenance needs | Smooth, continuous operation |

This table provides a glimpse into the quantifiable improvements that companies can expect as they adopt integrated solutions like the ROTOCON ERGT-800-1PRU.

The Broader Implications for Industrial Manufacturing and Automation

The impact of innovations like Meridian Laboratory’s new rotary ground solution extends beyond immediate operational benefits. It signals a broader trend in the industrial sector where efficiency, integration, and sustainability are becoming the watchwords of modern manufacturing. With ever-evolving challenges and the constant need to steer through the tangled issues of outdated processes, embracing these modern solutions has become both a strategic and operational imperative.

Enhancing Operational Agility

In today’s competitive market, industrial players must be agile and adaptable. The maintenance-free, integrated design of the ROTOCON ERGT-800-1PRU means that companies can more easily accommodate shifts in production requirements without the nerve-racking delays typically associated with system overhauls. This agility allows businesses to better meet consumer demands and adapt to rapid changes in technology, ultimately paving the way for enhanced productivity and competitiveness.

With the adoption of advanced rotary ground systems, manufacturers are poised to see improvements not only in day-to-day operations but also in the way they plan for long-term growth. The streamlined design capabilities of products like the ROTOCON ERGT-800-1PRU embody a forward-thinking approach—one where complex system upgrades become less intimidating and more a natural evolution towards efficiency.

Future-Proofing Industrial Operations

Looking ahead, it is clear that the future of industrial manufacturing will rely on systems that can seamlessly integrate with evolving technologies such as artificial intelligence and the Internet of Things (IoT). As companies continue to figure a path into the future, products that combine multiple functions into a single, reliable unit will be critical. The ROTOCON ERGT-800-1PRU serves as a prime example of a product built with future-readiness in mind. Its robust design not only addresses today’s requirements but is also well-equipped to support next-generation automation capabilities, ensuring that businesses remain competitive over the long haul.

Closing Thoughts: Setting a New Standard in Industrial Automation

The introduction of Meridian Laboratory’s ROTOCON ERGT-800-1PRU rotary ground and rotary union combination is more than just a technological upgrade—it is a milestone in the journey toward smarter, safer, and more resilient industrial automation. By addressing the tangled issues of traditional systems and eliminating routine maintenance hurdles, this innovative product stands as a testament to what is possible when engineering meets forward-thinking design.

In our view, as the industrial manufacturing landscape continues to evolve, the focus will no longer be solely on the immediate gains of automation but on creating systems that are robust, integrated, and sustainable. The product’s ability to provide uninterrupted performance, a unified system for both electrical grounding and shielding gas integration, and its overall ease of integration all point to a future where industrial operators no longer have to worry about navigating the confusing bits of outdated technology.

Looking at the bigger picture, Meridian Laboratory’s approach could well become the blueprint for future innovations in rotational welding and automated production processes. As companies worldwide grapple with the challenges of adoption and integration, solutions that are maintenance-free and robust will undoubtedly lead the way, carving out a path where technological upgrades are seen not as overwhelming burdens but as essential building blocks for sustainable growth.

Key Takeaways for Industry Leaders

- Integrated Solutions Streamline Processes: Products that combine electrical and fluid systems reduce maintenance hassles and boost overall efficiency.

- Reliability is Non-Negotiable: In an era of rapid production and tight schedules, maintenance-free operation is a must-have feature that prevents downtime.

- Future-Ready Engineering: As industries gear up for the next wave of automation technology, solutions that can seamlessly integrate into larger, smart systems are key to staying competitive.

- Global Partnerships Matter: With the trend toward integrated manufacturing, strong collaborations between OEMs, system integrators, and suppliers will be essential for sustained growth in the industry.

These takeaways are not merely observations but actionable insights for companies seeking to refine their processes and stay ahead of the curve in an ever-evolving automation landscape.

Final Reflections

Ultimately, products like Meridian Laboratory’s ROTOCON ERGT-800-1PRU represent a significant leap forward for industries that operate at the cutting edge of technological advancements. As the industrial sector continues to evolve amidst new challenges and opportunities, embracing innovative solutions that simplify operations, reduce routine maintenance, and enhance overall safety will be more critical than ever. Companies that choose to invest in such integrated, robust technologies will not only improve their current production processes but also set themselves up for long-term success in a market that shows no signs of slowing down.

In summary, the ROTOCON ERGT-800-1PRU is a beacon of what diligent research, smart engineering, and a clear understanding of operational pain points can achieve. It is a product that manages to effectively address the tricky parts of conventional systems, streamline complex operations, and future-proof the competitive industrial landscape. For those in the manufacturing and automation sectors, this innovative solution is a clear sign of the exciting possibilities that lie on the horizon as we continue to figure our way through the evolving corridors of technological progress.

We look forward to seeing how this innovative product inspires further advancements in the field of automated welding and broader industrial automation. As businesses continue to adapt and evolve, embracing tools that simplify complex operations and boost operational efficiency will be critical to achieving enduring success. The journey toward a more integrated, sustainable, and efficient manufacturing process is well underway—with the ROTOCON ERGT-800-1PRU leading the charge.

Ultimately, as this opinion editorial illustrates, the future of industrial automation is bright, filled with promise and potential. It is a future where technology and practicality converge to deliver robust products that not only meet but exceed the demands of modern industrial applications. In this ever-changing landscape, innovation remains the cornerstone of progress, and Meridian Laboratory’s latest offering is a shining example of how the industry can keep moving forward, confidently and efficiently.

Originally Post From https://www.automate.org/motion-control/news/all-in-one-rotary-electrical-ground-and-rotary-union-assembly-by-meridian-laboratory

Read more about this topic at

Alipis Aluminium Alloy Rotary Control Knob for Seamless …

Seamless integration: rotary encoder and microcontroller