Introducing a New Era in Welding Automation

The manufacturing landscape is on the brink of a major transformation with the introduction of the world’s first fully autonomous TIG welding solution developed right here in British Columbia. This breakthrough innovation, unveiled under the name SWR™ TIPTIG Autonomy, is setting new standards in precision, efficiency, and safety—ushering in a fresh chapter for advanced manufacturing industries globally. In an environment where traditional methods often come with tricky parts and tangled issues, the latest advancements in artificial intelligence and machine learning are providing a welcome remedy to overcome the confusing bits of manual welding.

The need to upgrade legacy systems has always been a pressing matter in industries such as shipbuilding, nuclear, energy, and clean technology. With the rigors of manual TIG welding long reliant on the expertise of highly skilled welders, a solution that promises to reduce the nerve-racking reliance on human precision while enhancing productivity is seen as nothing short of revolutionary. SWR™ TIPTIG Autonomy is playing a pivotal role in shaping the future by automating a process known for its complicated pieces, ensuring consistent quality that was often marred by human error.

Revolutionary Technology: SWR™ TIPTIG Autonomy Unpacked

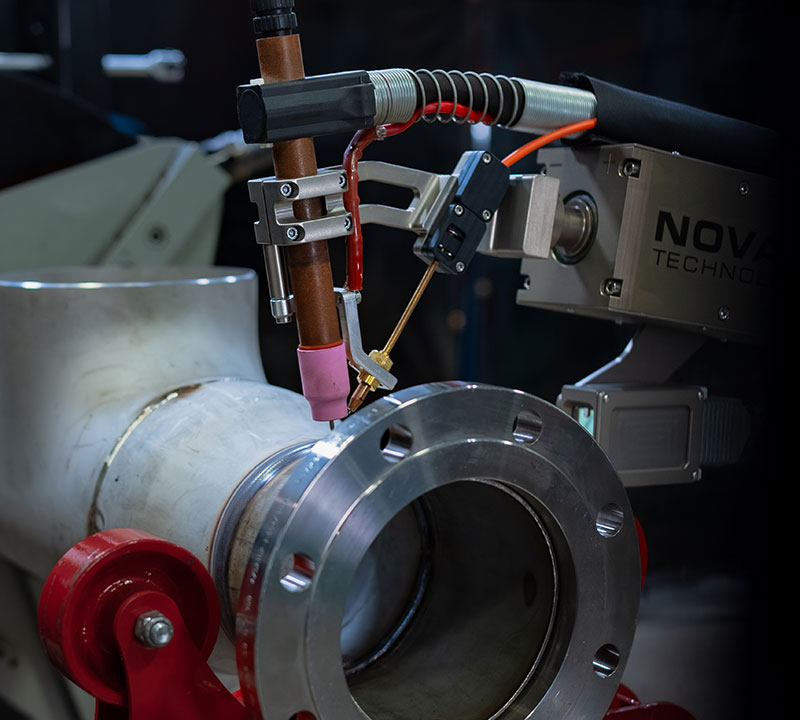

The unveiling of SWR™ TIPTIG Autonomy represents not just a technological milestone, but also a strong national endorsement of advanced manufacturing capabilities. Developed by Novarc Technologies Inc.—a full-stack AI robotics company with a strong reputation in automated welding—the new solution integrates artificial intelligence with cutting-edge machine learning. This marks a significant evolution from traditional TIG welding techniques that were once dependent on the manual dexterity of expert welders.

At its launch event in Burnaby, British Columbia, industry leaders and government officials alike celebrated this technological leap. The event brought together figures such as Wade Chang, the Member of Parliament for Burnaby Central; Paul Choi, who serves as the Parliamentary Secretary for Trade; and Soroush Karimzadeh, the Co-founder and CEO of Novarc. Their combined support underscores the critical role that innovative welding technology plays in driving Canada’s advanced manufacturing sector forward.

Addressing the Tricky Parts of Traditional TIG Welding

For decades, TIG welding has demanded exceptional finesse, with its success hinging on the unpredictable nuances associated with manual control. Welders consistently had to manage the fine points of heat control, angle adjustments, and material consistency—all tasks laden with confusing bits and subtle twists. By automating these processes, SWR™ TIPTIG Autonomy is not only optimizing weld quality but also freeing skilled labor to focus on more strategic and less physically taxing roles. This shift significantly eases the overwhelming and sometimes intimidating responsibility placed on human operators during high-stakes production environments.

The fundamental advantage here is that automation can minimize the likelihood of error. Traditional welding methods, replete with hidden complexities, often required the operator to make split-second decisions. With AI-driven precision, the system can take a closer look at each weld in real time, ensure that every pass is executed with exactitude, and maintain high standards uniformly—eliminating those slight differences that have historically led to variations in weld quality.

Enhancing Productivity Amid Skilled Labor Shortages

Across North America, manufacturers have faced a persistent shortage of skilled welders. This labor gap has long been a challenge, burdening companies with the dual pressures of maintaining quality and satisfying rising production demands. SWR™ TIPTIG Autonomy offers a promising solution by mitigating the dependency on manual expertise. With a fully autonomous system in operation, companies are better equipped to manage production schedules without the risk of human fatigue or error, thereby steering through the intense demand periods with enhanced efficiency.

By addressing these labor shortages head-on, the technology not only ensures better productivity but also paves the way for manufacturers to broaden their operational capacity in a cost-effective manner. The technology’s impact on the industry is multifold: reducing potential accidents in hazardous work environments, improving consistency across welds, and lending manufacturers the freedom to deploy their human capital into roles that require creative problem-solving and strategic oversight.

Integrating AI and Machine Learning: A New Frontier in Welding

Artificial intelligence is not a buzzword in the manufacturing realm—it’s now at the heart of tomorrow’s production lines. The SWR™ TIPTIG Autonomy system integrates sophisticated AI algorithms with state-of-the-art machine learning techniques. This synergy allows the welding solution to adapt dynamically to different materials, environmental conditions, and design specifications, ensuring that every weld is executed with precision that was previously seen as unattainable.

This technological leap is critical for industries that operate under strict safety and quality standards. The ability of AI to process countless variables in real-time allows for minute adjustments during the welding process, capturing even the smallest twists in welding arcs or shifts in heat distribution. As a result, manufacturers can now enjoy a level of consistency once thought to be the exclusive domain of highly trained welders—now available at the push of a button.

Machine Learning: Refining the Art of Precision Welding

The implementation of machine learning into the welding process is a key contributor to the consistently high quality of SWR™ TIPTIG Autonomy’s output. By continuously analyzing data from each weld, the AI system can learn from past sessions and adjust parameters to avoid repeating mistakes. This self-improving loop enables a degree of precision that evolves over time—addressing and compensating for tricky parts and subtle details that occur during production.

Welding, by nature, involves a host of variables such as metal composition, joint design, and environmental factors like temperature and humidity. The AI system is equipped to understand these factors, providing operators with detailed diagnostics and actionable insights. This intelligent feedback loop makes the system particularly effective in meeting the fine shades of distinctions required in high-stakes industrial projects.

Real-World Applications: Impact on Shipbuilding, Nuclear, Energy, and Clean Technology

One of the most exciting aspects of this innovation is its versatility across various industrial sectors. In an industry where precision and safety are paramount, SWR™ TIPTIG Autonomy is proving to be a game changer. Here are a few ways in which the technology is expected to significantly benefit key sectors:

- Shipbuilding: For a sector that often confronts challenging materials and complex structural designs, fully autonomous welding ensures that every joint meets rigorous safety and durability standards.

- Nuclear: Safety is of utmost importance in nuclear applications. By reducing the scope of human error, the technology brings an extra layer of reliability in fabricating deep-worn components for high-risk environments.

- Energy: From pipelines to power plants, enhanced precision in welding translates into stronger bonds and fewer weak spots, essential for maintaining industry benchmarks in safety and performance.

- Clean Technology: As clean energy sources and eco-friendly designs gain momentum, the ability to maintain high production quality with minimal environmental waste is critical. Automated welding contributes to efficient manufacturing while reducing the potential for material wastage.

These applications highlight just how extensive the benefits of automation can be. As the need to find your way through the challenging parts of production continues to grow, intelligent automation solutions are proving that technology can indeed streamline even the most intricate industrial processes.

Government Support and Investments: A Boost for Canadian Manufacturing

The launch of SWR™ TIPTIG Autonomy has also captured the attention of government figures who recognize the importance of innovative manufacturing solutions. Leaders such as the Honourable Gregor Robertson, Minister of Housing and Infrastructure, and the Parliamentary Secretary for Trade, Paul Choi, have voiced strong support for this development. Their advocacy emphasizes the system’s potential to not only uplift the manufacturing sector but also to enhance workers’ safety and overall productivity.

This backing from government officials indicates a broader trend where policymakers are aligning with cutting-edge industries to boost the nation’s economic standing. Their investment in technology, particularly in areas like AI and robotics, signals readiness to take on the overwhelming challenges industries face—ranging from rapidly evolving market demands to the nerve-racking shortage of skilled labor.

Strategic Investment in Advanced Manufacturing Technology

Government investment, as part of broader economic development initiatives, plays a super important role in nurturing such innovations. In British Columbia, the commitment to supporting technology startups and research and development is paving the way for a more robust manufacturing ecosystem. This environment is ripe for growth, allowing companies like Novarc Technologies Inc. to experiment, innovate, and ultimately deliver solutions that have a wide-reaching impact on the economy.

These strategic moves help ensure that manufacturers are not left stranded when faced with off-putting challenges. Instead, they’re equipped with technologies that help figure a path through even the most overwhelming aspects of production. The infusion of government support into the high-tech sector also signals to private investors that the future of manufacturing is both secure and promising.

Bridging the Gap: The Role of Public-Private Partnerships

Public-private partnerships are essential for driving breakthroughs in industrial sectors. By collaborating closely with tech innovators, government bodies are helping industries overcome the small, yet significant, hurdles presented by conventional manufacturing techniques. These collaborations serve to bridge the gap between the existing infrastructure and new-age production methods, ensuring that innovations like SWR™ TIPTIG Autonomy become part of a broader narrative of progress in Canadian industry.

This model of cooperation has several benefits:

- Resource Sharing: Public-private partnerships enable resource pooling, which can supercharge development processes and drive rapid innovation.

- Risk Reduction: The combined expertise helps manufacturers manage and mitigate risks associated with complicated production processes that once seemed overwhelmingly unpredictable.

- Market Expansion: Strong governmental backing adds credibility to new technologies, accelerating market penetration on both national and international fronts.

In practical terms, this means that manufacturing facilities can integrate new technologies more smoothly and with greater confidence, knowing that they are backed by robust support systems and a collaborative network aimed at long-term success.

Diving Into the Benefits: How Autonomous Welding Enhances Productivity

One of the key selling points of the SWR™ TIPTIG Autonomy system is its ability to significantly boost productivity. By leveraging AI and robotics, the system provides not only precise control over the welding process but also the flexibility to adapt quickly to different operational conditions. The result is a dramatic uptick in production efficiency that’s essential for maintaining a competitive edge in today’s fast-paced industrial environments.

Here are some of the standout benefits that manufacturers can expect from employing this fully autonomous welding solution:

- Consistent Weld Quality: By eliminating human error, the system delivers uniform joints that meet rigorous quality standards.

- Improved Safety: Automated processes reduce worker exposure to potentially hazardous conditions and off-putting physical strains.

- Cost Efficiency: Reducing dependency on highly skilled manual labour can lower training costs and operational overheads.

- Higher Throughput: With the system’s ability to operate continuously and make real-time adjustments, production lines can work at a faster pace without sacrificing precision.

- Data-Driven Insights: The integration of AI allows manufacturers to gather valuable data on operational performance, paving the way for fine-tuning processes and preemptively addressing issues before they escalate into larger problems.

With these benefits, the SWR™ TIPTIG Autonomy system is not just a technological upgrade—it’s an essential tool in rethinking how manufactured goods are produced in an age defined by rapid technological advancements. The system’s AI-driven nature ensures that every intricate twist in the process is managed efficiently, providing a valuable edge in scenarios where managing your way through production challenges requires both innovation and precision.

The Future of Welding Solutions: Insights and Next Steps

As we look ahead, the evolution of welding technology appears both promising and necessary. SWR™ TIPTIG Autonomy sets the stage for the next generation of welding solutions that will increasingly rely on autonomous systems and smart robotics. The pathway forward involves not just adopting cutting-edge technology but also rethinking traditional manufacturing methods that have long been riddled with tension and off-putting reliance on manual labor.

While there are always a few bumps along the path of innovation, this breakthrough technology is a perfect example of how industry leaders can work through the daunting challenges posed by modern production requirements. By pushing the boundaries of what automation can achieve, the system demonstrates that even the trickiest parts of welding can be made simpler and more predictable with the right mix of technology and innovation.

Key Considerations for the Next Wave of Industrial Automation

For businesses looking to integrate such innovative systems, there are several points to consider. These include:

- Integration with Existing Systems: Companies must assess how well new automation solutions can mesh with current manufacturing setups. In many cases, incremental upgrades are easier to manage than complete overhauls.

- Training and Skill Development: While automation reduces the dependency on manual labor, there remains a need for skilled technicians who can oversee complex systems and ensure that the automation runs smoothly. Investing in staff training provides a super important foundation for future success.

- Maintenance and Ongoing Optimization: High-tech systems require regular maintenance and consistent updates to stay ahead of potential issues. Companies must set aside resources to manage the continuous evolution of these autonomous platforms.

- Data Security and Privacy: With any internet-connected AI system, the importance of safeguarding operational data cannot be overstated. Ensuring robust cybersecurity measures are in place is key to a reliable setup.

By taking these factors into account, manufacturers can better equip themselves to figure a path toward a seamless transition into a future where autonomous welding solutions become the norm rather than the exception.

Technology Roadmap: Incorporating Emerging Trends

Looking into the foreseeable future, it is clear that we are only scratching the surface of what AI and robotics can do for industrial welding. Manufacturers are now being encouraged to take a closer look at emerging trends that include real-time analytics, predictive maintenance, and further integration of complementary technologies such as augmented reality for enhanced oversight.

Consider the following roadmap illustrating how technology might evolve in the next five years:

| Timeframe | Emerging Trends | Potential Impact |

|---|---|---|

| 1-2 Years | Integration of Advanced Sensors and Real-Time Monitoring | Enhanced process control and immediate correction of slight deviations during welding. |

| 2-3 Years | Predictive Analytics and Maintenance Scheduling | Minimized downtime by predicting equipment needs and preventing unforeseen failures. |

| 3-5 Years | Integration with Augmented Reality (AR) Systems | Improved operator oversight and troubleshooting with visual data overlays. |

Each of these trends underscores the ongoing quest to manage your way through production challenges with smarter, more intuitive systems. As manufacturers become more familiar with these tools, the benefits will ripple out to improve overall production quality, safety standards, and cost-efficiency.

Industry Perspectives: The Broader Impact of Automated Welding

The advent of a fully autonomous welding solution like SWR™ TIPTIG Autonomy is more than just a technological leap—it heralds a sea change in how industries operate. With a blend of precision, speed, and reliability, the system is set to redefine workflows in many industrial sectors.

Industry experts have noted that integrating AI into welding is a surefire way to address not only existing production hurdles but also some of the subtle parts that have, until now, been difficult to manage manually. Leveraging this technology means that companies can focus on strategically important tasks while leaving the repetitive and sometimes intimidating aspects of welding to a precise, automated process.

With these developments, manufacturing companies are beginning to see automation not as a replacement for human skill but as a complementary force. The combination of human oversight with machine precision creates an environment where the strengths of both can be maximized, and the pitfalls of traditional methods can be largely eliminated.

Benefits Summarized: A Recap for Decision Makers

For executives and managers deliberating the next steps in their manufacturing strategies, the advantages of adopting systems like SWR™ TIPTIG Autonomy can be summarized as follows:

- Enhanced Quality: Consistent and precise welds lead to superior products and reduced rates of rework.

- Operational Efficiency: Automation accelerates production timelines, resulting in lower overall costs and increased throughput.

- Safety Improvements: Minimizing hazardous manual tasks reduces workplace incidents and fosters a safer working environment.

- Adaptive Technology: The system’s ability to learn from each weld ensures ongoing enhancements without additional human intervention.

- Economic Competitiveness: With faster production and reduced errors, companies are better positioned to meet market demands and expand their operations.

Integrating these benefits into a company’s strategic planning can make all the difference when it comes to staying ahead in a market that is both full of problems and filled with opportunity. The marriage of advanced robotics and AI is not only streamlining present-day production challenges but also setting a solid foundation for a future rich with innovation.

Charting a Path Forward in the Welding Industry

In conclusion, the launch of the SWR™ TIPTIG Autonomy system by Novarc Technologies Inc. marks a turning point for not only the welding industry but also for advanced manufacturing as a whole. As the technology continues to evolve, companies will need to get into the details of how best to implement these systems, taking into account both the advantages and the subtle parts that may require additional attention.

The path forward will require a collaborative effort between industry stakeholders, government entities, and technology providers. By working together to overcome the small twists and intricate challenges inherent in traditional manual welding, we can create a manufacturing landscape that is much safer, more efficient, and well-prepared to tackle the overwhelming demands of a technologically advanced era.

Future Considerations for Manufacturers

For those in the manufacturing sector evaluating new investments and production methodologies, the lessons offered by this innovative welding solution are clear:

- Invest in Versatility: Look for technologies that are adaptable across diverse applications and can be integrated with existing systems with minimal disruption.

- Embrace Continuous Learning: Technologies rooted in AI offer the advantage of evolving over time. Staying abreast of these advancements will ensure that your operations remain cutting edge.

- Prioritize Worker Safety: Automation that reduces the need for manual intervention in potentially dangerous tasks is a win-win for both employers and employees.

- Focus on Long-Term ROI: While the initial investment might seem intimidating, the long-term gains in efficiency, quality, and reduced labor costs are key benefits that must not be overlooked.

These considerations are critical in a time when the pace of technological change is accelerating. Businesses that take the initiative to adopt such innovations not only secure their competitive advantage but also contribute significantly to the broader narrative of industrial evolution that prioritizes both human ingenuity and machine precision.

Embracing Change: A Cultural Shift in Manufacturing

Adopting advanced autonomous systems represents more than a technical upgrade—it calls for a shift in workplace culture. Manufacturers will need to encourage a mindset that is open to change, ready to shift from traditional methods to a more integrated, AI-driven process. This involves rethinking long-held practices and embracing the continuous evolution of technology to manage and get around even the most nerve-racking production challenges.

As we move forward, it is essential for decision-makers to foster an environment where innovation is not only accepted but celebrated. By doing so, organizations can turn potentially intimidating changes into clear opportunities, ensuring that every member of the team understands the benefits of a technology-enhanced workplace.

Conclusion: A Promising Horizon for Advanced Manufacturing

The unveiling of the SWR™ TIPTIG Autonomy system is a testament to what can be achieved when cutting-edge technology meets a commitment to precision manufacturing. This innovation is more than just a new tool—it is a catalyst for change in an industry that has long been burdened by the tricky parts and overwhelming challenges of manual TIG welding.

With strong support from government officials and deep roots in British Columbia’s thriving technology ecosystem, this development heralds a new era in welding automation. The system stands out as a prime example of how emerging technologies can address the small distinctions that have long hindered consistent weld quality while simultaneously providing a solution to skilled labor shortages.

Going forward, the integration of AI and robotics in welding is expected to continue evolving, enabling industries worldwide to find their way through the tangled issues of production. As more manufacturers get into the details of automation, we can be confident that the future of advanced manufacturing will be defined by efficiency, safety, and a continuous pursuit of technological excellence.

In a time when every aspect of the economy is being reshaped by digital transformation, the SWR™ TIPTIG Autonomy system is a beacon of innovation that provides both a roadmap and a tangible solution for companies facing the daunting challenges of modern production. It proves that even in industrial settings where traditional methods once ruled, there is now a super important and effective way to steer through the unpredictable twists and turns of the manufacturing process.

The journey ahead is one where collaborative efforts between technology, government, and industry leaders will be key to unlocking even greater potential. As we embrace this change with open minds and a commitment to excellence, the welding industry—along with the broader manufacturing landscape—stands at the brink of an exciting new age characterized by unparalleled precision, enhanced safety, and a resilient foundation for future growth.

Ultimately, the success of SWR™ TIPTIG Autonomy symbolizes more than a single innovation. It represents a transformative shift in the way we think about, plan for, and execute industrial tasks. The advances in autonomous welding technology offer a clear signal to manufacturers everywhere: the future is here, and it is driven by smart, adaptable, and increasingly independent systems that promise to revolutionize our approach to production.

For those in the manufacturing world looking to future-proof their operations, the message is clear—embrace automation, invest in innovation, and prepare to reap the benefits of a system that takes the guesswork out of one of the most challenging parts of fabrication. As industries continue to evolve, leaders will undoubtedly look back on this moment as the turning point when traditional methods gave way to a new era of precision, efficiency, and boundless opportunity.

As we chart our course through this rapidly evolving landscape, let us remain committed to harnessing technology’s full potential. The new autonomous TIG welding solution is not just a tool—it is a signal that the future of manufacturing is a dynamic blend of human ingenuity and machine perfection, working together to build a safer, more productive, and more resilient industrial environment.

Originally Post From https://www.manilatimes.net/2025/11/01/tmt-newswire/globenewswire/novarc-reveals-the-worlds-first-fully-autonomous-tig-welding-solution-built-in-british-columbia/2213429

Read more about this topic at

The Evolution of Welding Automation: From Blacksmithing …

The Evolution of Robotic Welding